Or change the new technology of chip manufacturing, "electronic bath", to solve the challenges of film electronics

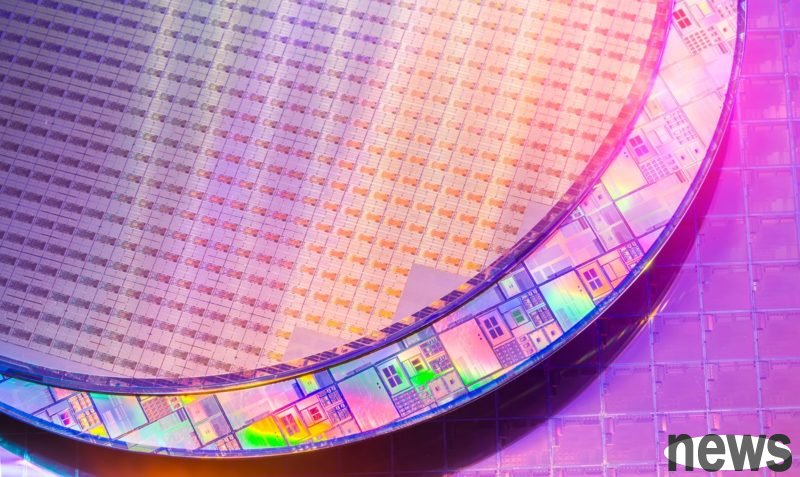

High power pivoting magnetron emission (HiPIMS) has made important progress recently, and the new technology is called "electronic bath", which has the potential to modify wafer production and improve the manufacturing efficiency and accuracy of microelectronic components.

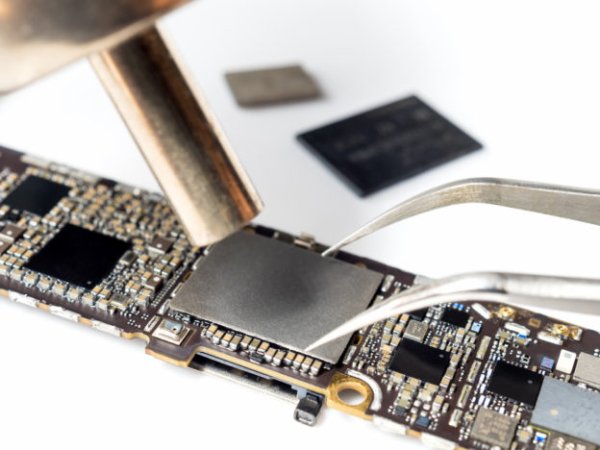

Theteam successfully produced high-quality pressure films at relatively low temperatures on insulated substrates using HiPIMS, which is the first time in the industry. Films play an important role in wireless equipment, can ensure correct reception of signals, and are used in sensors, actuators, and energy harvesting systems.

Innovations are very important for the performance of the pressure film when accurately controlling the formation of thin films to prevent unnecessary air and disorders from entering the film. With precise time control, the team can only accelerate the required ion when the film grows, improving the film quality.

Another breakthrough is the ability to produce films on insulated substrates, which are important to semiconductors, as many production tools cannot apply voltage to insulated substrates. The team calls the new method synchronous floating potential HiPIMS (SFP-HiPIMS), which is advantageous in producing high-quality pressure films at low temperatures, opening up a new path for wafer and electronic component production.

The development of iron films will be launched after theteam, which is the key area of current and future electronic technology. It will also cooperate with other research institutions to use photonics and quantum technology, and optimize processes with machine learning and high-throughput practical experiments.

The “Electron Shower” That’s Revolutionizing Microchip Manufacturing Eco-Friendly Breakthrough in Microchip Manufacturing Low temperature deposit of functional thin films on insulating substrates enabled by selective ion acceleration using synchronized floating potential HiPIMS